Maximize the Value of your Shale Assets

GeoScience

Engineering

Maximize the Value of your Assets

GeoScience  Engineering

Engineering

-

Subsurface

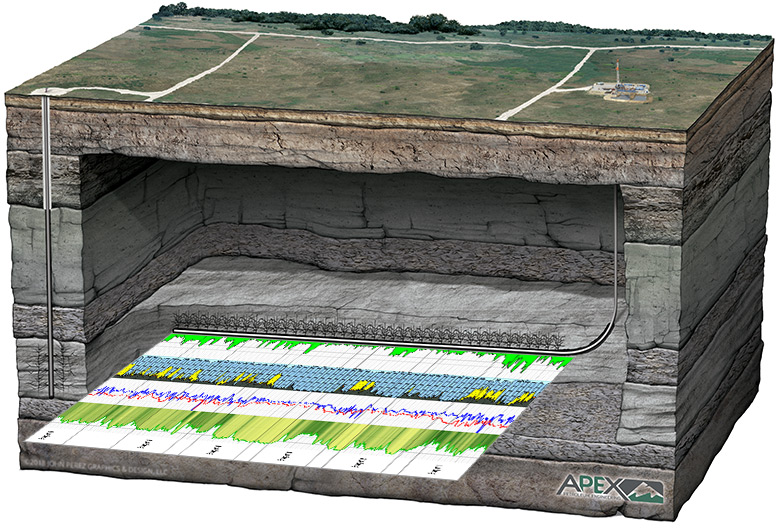

Quantify the Reservoir

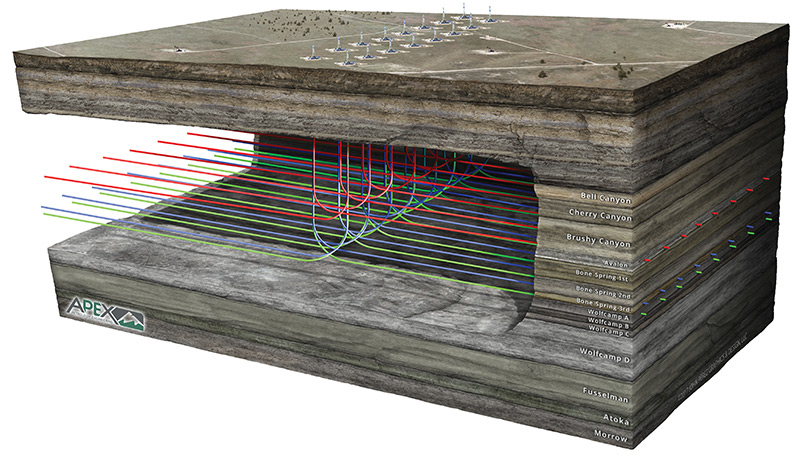

An unconventional asset presents numerous challenges that can drastically impact cost and performance.

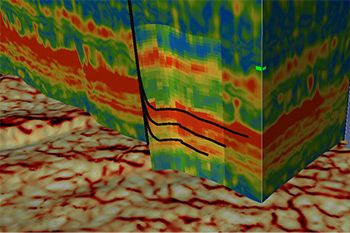

Our 3D Earth Models incorporate all of the available geoengineering data providing a thorough vision into your reservoir so you can accurately find the sweet spots and avoid the geohazards.

-

Stimulation

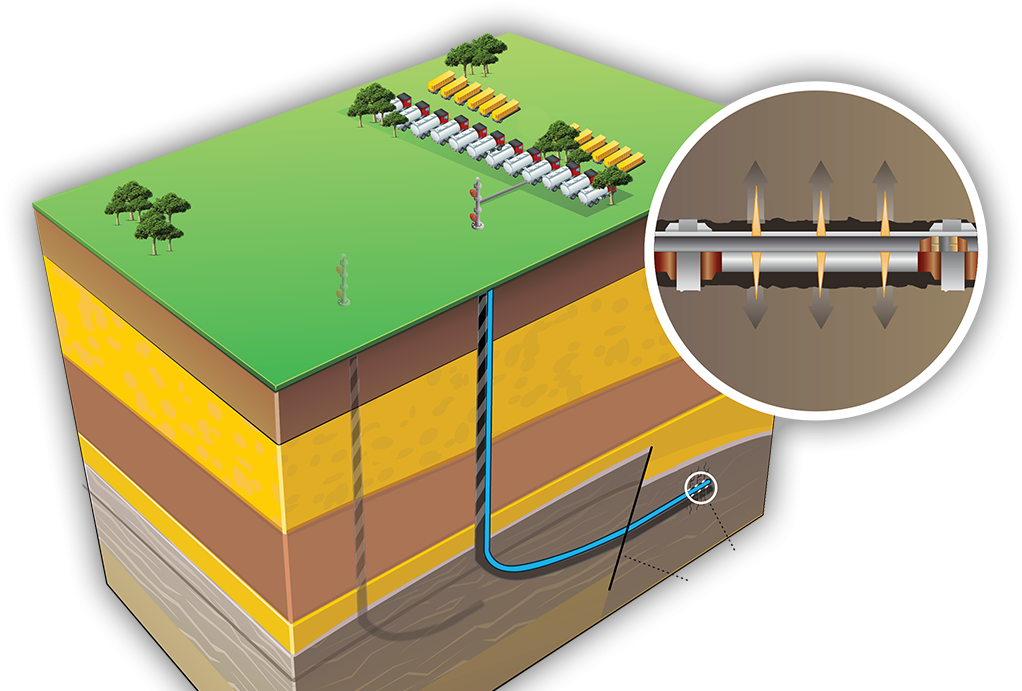

Exploit the Reservoir

Our Earth Model-based completion designs are driven by an MV-NPV analysis allowing us to optimize critical stimulation parameters, understand sensitivities in the design, and deliver an efficient well site frac operation.

-

Wellsite

Frac the Reservoir

This is where it all started in 1999. Helping operators call frac jobs at the wellsite was our core business then and remains our core business now. Through expanded services preparing for the frac and learning after the frac APEX engineers deliver a comprehensive integrated service that is truly the best in class.

-

Validation

Produce the Reservoir

Our team utilizes a comprehensive “look back” playbook to assure that the model, design, and wellsite operations are always evolving towards better wells. We deliver success throughout the process to ensure that production meets expectations.

Optimizing Well Performance

Completion & Reservoir Engineering

APEX Petroleum Engineering can provide you with everything you need to know to deliver profitable results on time and under budget. Get the complete guide to optimize your field development strategy & predict well performance.

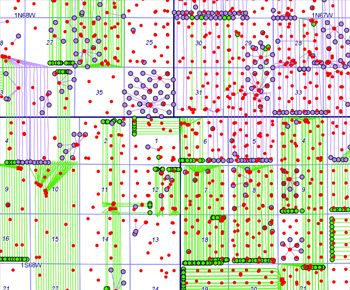

Well / Pad Placement

Understanding the subsurface ahead of planning well and pad placement is critical to maximizing production and minimizing costs. APEX excels in building detailed reservoir models so that a development plan can be evaluated at the field or asset level.

Speak to an Expert

Wellsite Frac Supervision

Ineffective treatment placement and screen-outs are extremely costly, typically resulting in under stimulated rock and lower well production. APEX engineers micromanage the pressure response in real time eliminating most problems before they become unmanageable. APEX engineers are your advocate on site and execute the treatment to your standards.

Speak to an Expert

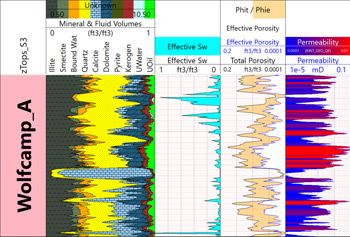

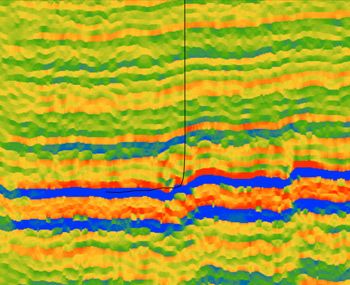

Landing Zone

Picking the ideal landing zone and staying in zone along the entire length of the lateral is directly related to well performance. APEX has all of the technology and expertise to make this a strength of your completion program.

Speak to an Expert

Wellbore Azimuth & Inclination

A lot of time and effort is put into analyzing wellbore azimuth and based on historical horizontal drilling no one really understands what controls this. APEX has incorporated state of the art geomechanical analysis into its subsurface modeling workflow so you can quantify the magnitude and direction of horizontal stress and drill wells to efficiently exploit this.

Speak to an Expert

Lateral Length

Horizontal wellbore length has grown from ~3000 feet a decade ago to 10,000+ feet today with no signs of slowing. APEX will help you understand heterogeneity along a proposed lateral so informed decisions can be made on lateral length performance vs. cost to drill and complete.

Speak to an Expert

Hazard Avoidance

Identifying geohazards along a well is just as important as understanding sweet spots in your reservoir. APEX uses all data available to map faults and fracture systems along with identifying zones that are overpressured and unstable.

Speak to an Expert

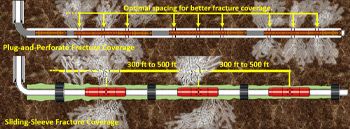

Completion Technique

Oil and gas companies utilize two completion technologies; “plug-and-perf” and “sliding sleeves” to efficiently extract hydrocarbons along a horizontal well. The jury is still out on which is the best approach as both have been used effectively in most shale reservoirs. APEX can help you understand the technical and operational tradeoffs of these two methods specific to your reservoir.

Speak to an Expert

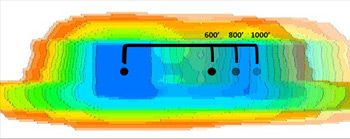

Completion Design

No bigger question comes to mind when planning a completion than whether to implement a geometric versus an engineered design. APEX builds detailed mechanical earth models so that stage and perf locations can be systematically evaluated in the frac simulator and informed decisions made on which method works best.

Speak to an Expert

Treatment Type, Volume & Duration, Rate & Pressure

APEX believes that good frac’ing applied to a good reservoir yields better wells. APEX utilizes a unique multivariate-net present value (MV-NPV) workflow to optimize frac properties against the earth model. Hundreds of simulations are run to evaluate the interaction of key frac variables and practical recommendations are provided. Integration of these results utilizing an economic model determines the optimum combination of completion and stimulation designs.

Speak to an Expert

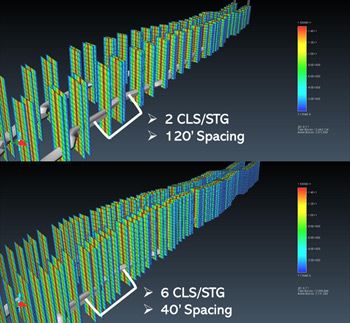

Lateral Spacing

Optimum well spacing is defined as the vertical and horizontal spacing at which the areal influence of adjacent wells results in zero impact on well performance and efficiency. APEX engineers use a combination of multivariate economic optimization and numerical reservoir simulation to provide recommendations based on production forecasts derived from the analysis.

Speak to an ExpertExperience

Value

Accuracy

Challenges

Solutions

$uccess

- Bakken Shale

Average EUR increased to 1,200 MBOE; a 60% increase in asset value. - Qatar Offshore Field

Production and injection volumes tripled. - Bahrain

Production rates of 20-30+ MMCFD.